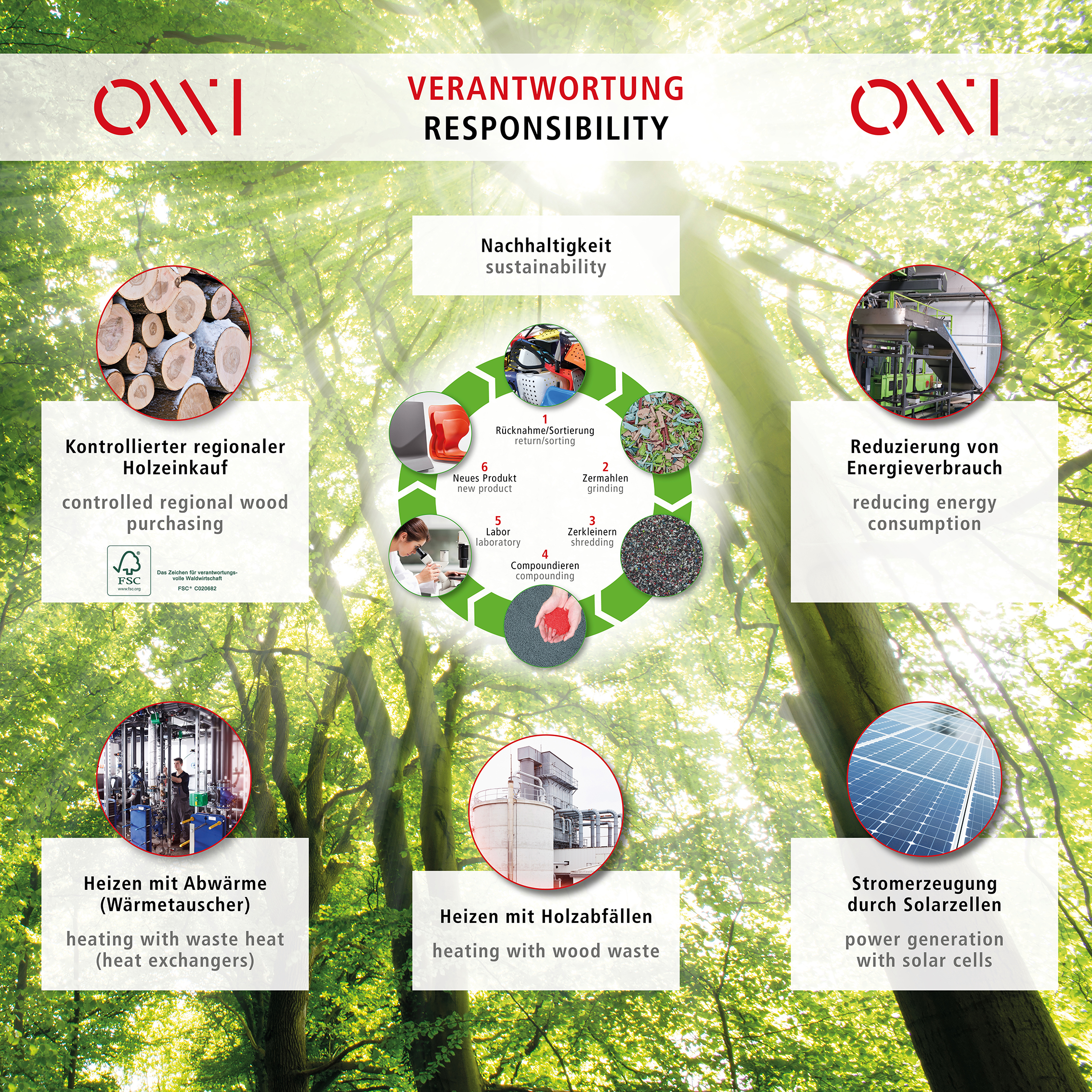

SUSTAINABILITY

Home > Sustainability

SUSTAINABILITY

For over 90 years, the sustainable use of natural resources has been part of our corporate philosophy. The preservation of the environment and the protection of the climate are not only a business concern for us, but also a very personal one. With our actions today, we stand by our responsibility for the future. With our actions today, we stand by our responsibility for the future, and who better to implement this than a family business.

We want to transfer our company and its land to the next generation with a clear conscience.

FSC ® CERTIFICATION

Since 2016, OWI is also FSC ® – (license no. FSC-C020682) certified.

PLASTIC – RECYCLING & ECOLOGY

In our company we only process thermoplastics, mostly polypropylene (PP), polyamide (PA) and ABS. These plastics are 100% recyclable.

In 2021, the “compounding plant” project was launched. For this purpose, a new testing laboratory and the necessary production equipment will be installed to produce our own re-compounds.

With regard to ecology, we are permanently increasing the usage of regenerates / re-compounds made from post production plastic and post consumer plastic as well as bio-compounds. In the course of the last 5 years, the share has increased from 7.5% to 20% – and the trend is still rising.

PHOTOVOLTAIC SYSTEMS

Since 2010, more than 800 modules with a nominal output of 163 kWp have been installed on the roofs of our production facilities.

In spring / summer 2023, further photovoltaic modules with a total rated output of 1,080 kWp were installed, meaning that almost 3,400 modules now generate around 1,200,000 kWh of “solar power” per year. In this way, we avoid annual emissions of around 450 tons of CO2, which corresponds to the annual consumption of 330 four-person households.

The planned grid connection for the newly installed modules is scheduled for the end of 2023.

CO2 – NEUTRAL HEATING ENERGY

In our wood combustion plant, put into operation in 2019, we burn the production residues resulting from the plywood production.

The chip silo built for this purpose, which stores the production residues over the summer until the start of the heating period, has a total volume of 500 m3.

This enables us to generate almost all of our heating energy in a CO2-neutral manner from wood, a renewable raw material. Thanks to intelligent combustion control and state-of-the-art fine dust filter technology, we are well below the limit values for fine dust specified in the 1st BImSchV (2nd stage).

Thanks to new wood combustion, we were able to save more than 100 t of CO2 in 2020 compared to 2019.

SPRINKLER SYSTEM

In order to optimally protect our employees and production facilities in the event of a fire, our production halls are protected by a sprinkler system. For this purpose, 490 m3 of water are kept in the sprinkler basin. With the help of heat exchangers, the cold stored in the water is used to cool the process water of the compounding line. Thus, an annual consumption of approx. 800,000 liters of fresh water was saved. This corresponds roughly to the consumption of 8 households.

HEAT RECOVERY

Due to rising energy prices and higher demands on water management in the plastic injection moulding sector, we have been using a 500 kW 2-circuit cooling system since 2018, which cools the moulds on our injection moulding machines so that our plastic injection moulded parts retain their shape permanently. The resulting waste heat is then fed directly into our heating system and used to heat our logistics building.

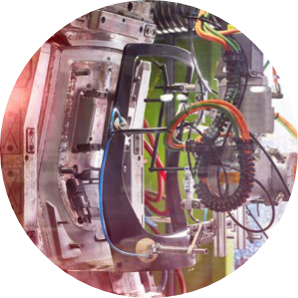

PRODUCTION FACILITIES

To better meet our responsibility for sustainability and environmental protection, since 2018 we have replaced three machines in our wood & plastics production with state of the art energy-efficient machines of the latest generation.

These have been convincing, so that we will consistently continue the acquisition of energy-efficient new machines in the future.

At the beginning of March 2021, we received another new injection moulding machine for our plastic production. This will result in electricity savings of more than 40% and CO2 savings of over 30 t per year.