OWI FireProtect

Homepage > OWI-FireProtect

OWI FireProtect

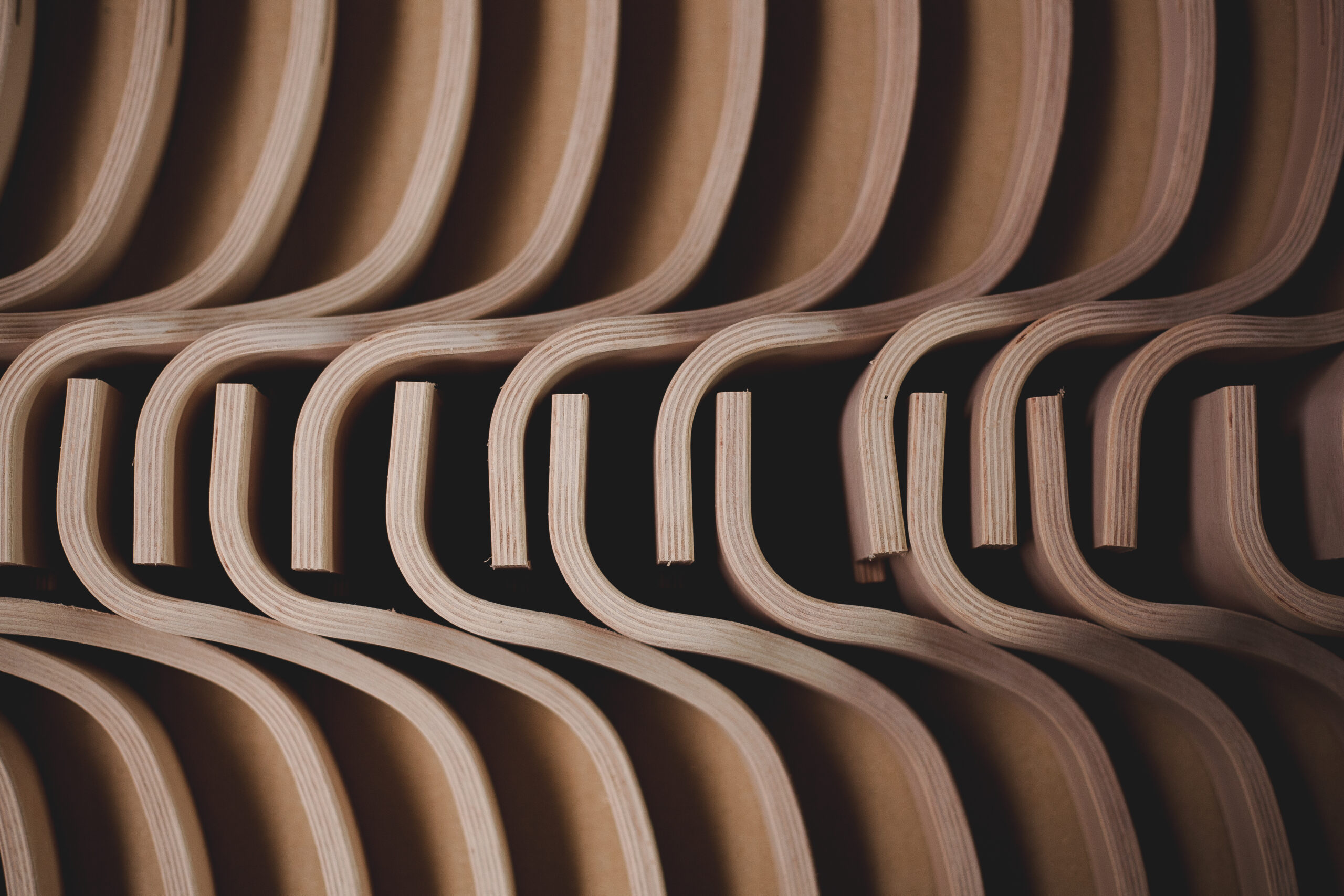

With OWI-FireProtect, we offer you flame-retardant molded parts made of wood from a wall thickness of 6 mm.

All OWI-FireProtect products consist of specially impregnated beech veneers, glued with a modified UF resin. All types of thermally heated press molds can be used in production. The technical and mechanical properties are comparable to those of our standard products and hardly differ.

This enables us to meet the increased fire protection requirements for applications such as seats for buses, trains, airport seating and much more.

Our OWI-FireProtect material is certified in accordance with the latest EN 45545-2:2020+A1:2023 standard and meets the strict requirements of requirement set R6 for hazard levels HL1 and HL2. OWI-FireProtect products with CPL surfaces even achieve certification for the highest hazard level HL3.

The reaction to fire test is carried out in accordance with DIN ISO 5660-1:2015+A1:2019 “Reaction to fire tests for building materials – Heat release, smoke generation and mass loss rate – Part 1: Heat release rate (cone calorimeter method) and smoke generation rate (dynamic measurement)”. A test certificate is available.

The smoke emission is tested according to DIN EN ISO 5659-2:2017 Plastics – Smoke emission – Part 2: Determination of optical density by single chamber test, smoke toxicity test according to EN 45545-2:2013+A1:2015, Annex C.

OWI-FireProtect Flyer![]()

OWI-FireProtect raw (classification report test reports)![]()

OWI-FireProtect CPL (classification report test reports)![]()

Product examples